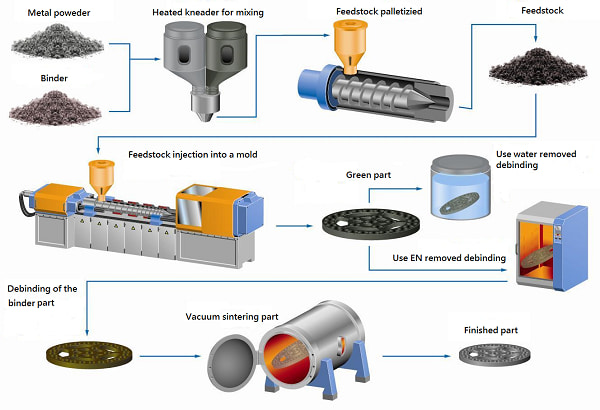

Metal injection molding (MIM) is a typical result of interdisciplinary, which integrates two completely different processing processes (plastic injection molding and powder metallurgy). So that designers can get rid of the traditional constraints and obtain low-cost and special-shaped stainless steel, nickel, iron, copper, titanium and other metal parts by plastic molding, so as to have greater design freedom than many other production processes. As a professional metal injection molding machine manufacturer, we provide services for customizing Mim products.

Metal injection molding is most suitable for mass production of small metal parts. As with injection molding, these components may be geometrically complex, thin-walled and detailed. Various ferrous and non-ferrous alloys can be used with metal powder, and the material properties (strength, hardness, wear resistance, corrosion resistance, etc.) are close to forged metal. In addition, since the metal does not melt in the metal injection molding process (different from the metal casting process), superalloys can be used without any negative impact on the tool life.